Top Benefits of Using Stainless Steel Gear Pumps in Industrial Systems

In industrial systems, selecting the right pump is critical for efficiency, reliability, and long-term performance. Stainless steel gear pumps have emerged as a preferred choice across a variety of industries, from chemical processing to food and beverage manufacturing. Known for their durability, corrosion resistance, and consistent performance, these pumps offer several advantages that make them essential for demanding applications.

This article explores the top benefits of using stainless steel gear pumps in industrial systems and highlights why choosing a reliable gear pump manufacturer is key to maximizing these advantages.

Understanding Stainless Steel Gear Pumps

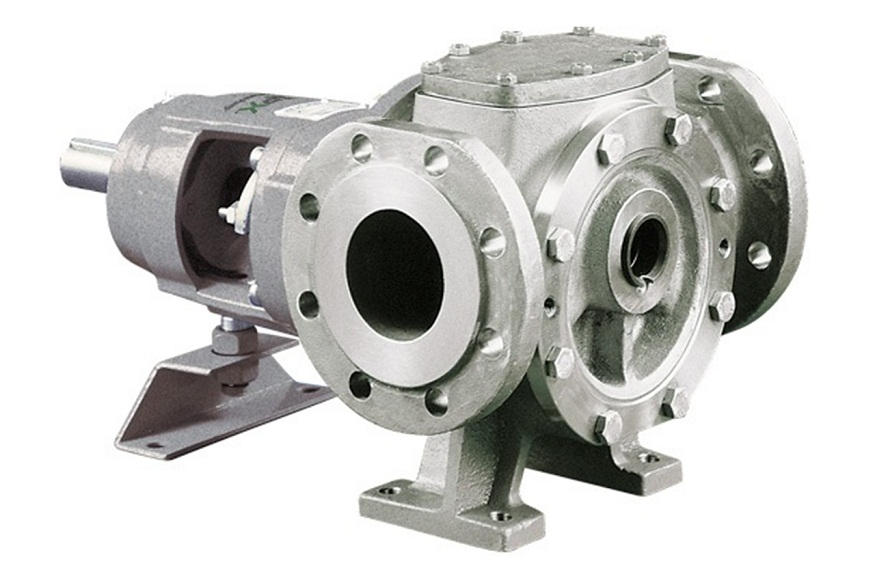

A stainless steel gear pump is a positive displacement pump that uses interlocking gears to move fluid through the system. As the gears rotate, fluid is trapped between the gear teeth and the pump casing, creating a consistent and continuous flow.

These pumps are particularly well-suited for handling viscous fluids, corrosive liquids, and high-temperature applications. Their construction from stainless steel ensures resistance to rust, chemical attack, and mechanical wear, which is critical in industries that demand reliability and hygiene.

Key Benefits of Stainless Steel Gear Pumps

1. Exceptional Corrosion Resistance

One of the primary advantages of stainless steel gear pumps is their superior resistance to corrosion. Unlike pumps made from traditional materials, stainless steel can withstand exposure to aggressive chemicals, acids, and other corrosive fluids.

- Ideal for chemical and pharmaceutical industries where fluids can degrade conventional pump materials

- Prevents contamination of sensitive liquids, maintaining product quality

- Reduces maintenance and replacement costs due to extended component life

This resistance makes stainless steel gear pumps an investment in long-term reliability and safety for industrial systems.

2. High Durability and Longevity

Stainless steel gear pumps are engineered to endure rigorous industrial operations. The robust construction ensures that the pump maintains performance even under high pressure, heavy loads, or continuous operation.

- Resistant to mechanical wear, scratches, and surface erosion

- Maintains precision in fluid transfer over extended periods

- Reduces downtime caused by pump failures

By choosing a high-quality pump from a reputable gear pump manufacturer, operators can ensure long-term performance and reliability in demanding applications.

3. Ability to Handle Viscous and Abrasive Fluids

Industrial systems often deal with fluids that are thick, viscous, or contain suspended solids. Stainless steel gear pumps excel in handling these challenging fluids without compromising flow or pressure.

- Smooth and continuous pumping ensures consistent delivery

- Minimizes shear, preserving the integrity of sensitive fluids

- Capable of moving slurries, oils, and high-viscosity liquids efficiently

This versatility allows industries to use a single pump type for multiple applications, simplifying system design and maintenance.

4. Hygienic and Easy to Clean

In the food, beverage, and pharmaceutical industries, hygiene is paramount. Stainless steel gear pumps are naturally suited to these environments due to their smooth surfaces and resistance to bacterial growth.

- Prevents contamination and maintains product safety

- Facilitates easy cleaning and sterilization

- Compliant with stringent industry standards for sanitary processing

These features make stainless steel gear pumps a preferred choice for applications requiring both performance and hygiene.

5. Precise and Consistent Flow

Positive displacement gear pumps are known for providing accurate, steady, and pulse-free flow. Stainless steel gear pumps maintain this precision, which is critical for industrial systems that require exact fluid metering or synchronized operation.

- Ensures smooth operation of machinery dependent on consistent lubrication or fluid transfer

- Reduces fluctuations that could affect product quality or system efficiency

- Supports high-pressure applications without compromising flow accuracy

Accurate flow control also minimizes wastage, contributing to cost savings over time.

6. Resistance to High Temperatures

Stainless steel gear pumps can operate under a wide range of temperatures without compromising performance. This makes them suitable for applications where fluids are heated or where ambient industrial temperatures are high.

- Prevents deformation or wear caused by thermal expansion

- Maintains performance for both low and high-temperature fluids

- Extends operational lifespan, even in extreme conditions

High-temperature resistance adds versatility, allowing a single pump to meet multiple operational requirements.

7. Low Maintenance and Operational Costs

While the initial investment in a stainless steel gear pump may be higher than that of alternative materials, the long-term benefits far outweigh the costs. Their durability, corrosion resistance, and efficiency reduce the frequency of repairs and replacements.

- Fewer breakdowns and reduced downtime

- Extended intervals between routine maintenance

- Lower total cost of ownership over the pump’s lifespan

Investing in a quality pump from a reputable gear pump manufacturer ensures that maintenance schedules are predictable and manageable.

Applications of Stainless Steel Gear Pumps

Stainless steel gear pumps are versatile and find applications across multiple industries:

- Chemical Industry: Safe transfer of corrosive liquids, acids, and solvents.

- Food and Beverage Industry: Hygienic pumping of sauces, syrups, oils, and other food-grade fluids.

- Pharmaceutical Industry: Precise handling of sensitive formulations under sterile conditions.

- Cosmetics Industry: Smooth transfer of creams, gels, and high-viscosity liquids.

- Oil and Gas: Handling of lubricating oils, hydraulic fluids, and other high-viscosity liquids.

In each case, the reliability, durability, and resistance of stainless steel gear pumps contribute to operational efficiency and product quality.

Choosing the Right Gear Pump Manufacturer

Selecting a trusted gear pump manufacturer is as important as selecting the pump itself. The manufacturer’s expertise determines the precision, material quality, and performance of the pump.

- Experience: Choose manufacturers with a proven track record in producing stainless steel gear pumps.

- Quality Materials: Ensure high-grade stainless steel and precision-engineered components.

- Customization Options: Look for manufacturers who can tailor pumps to your specific industrial requirements.

- Support and Service: Reliable manufacturers provide technical support, spare parts, and maintenance guidance.

- Testing and Certification: Pumps should undergo rigorous quality checks and comply with relevant industry standards.

Partnering with a reputable manufacturer ensures that your pump performs optimally while minimizing operational risks and maintenance issues.

Stainless steel gear pumps offer unparalleled benefits in industrial systems, including corrosion resistance, durability, precise flow, and compatibility with viscous or sensitive fluids. Their hygienic properties, temperature resistance, and low maintenance requirements make them indispensable across multiple industries.

Investing in a high-quality pump from a trusted gear pump manufacturer not only ensures long-term reliability but also optimizes system efficiency, reduces downtime, and enhances overall operational safety. For industrial operators seeking consistent performance, minimal maintenance, and extended pump life, stainless steel gear pumps provide a robust and versatile solution.